- توان (کیلووات): 15

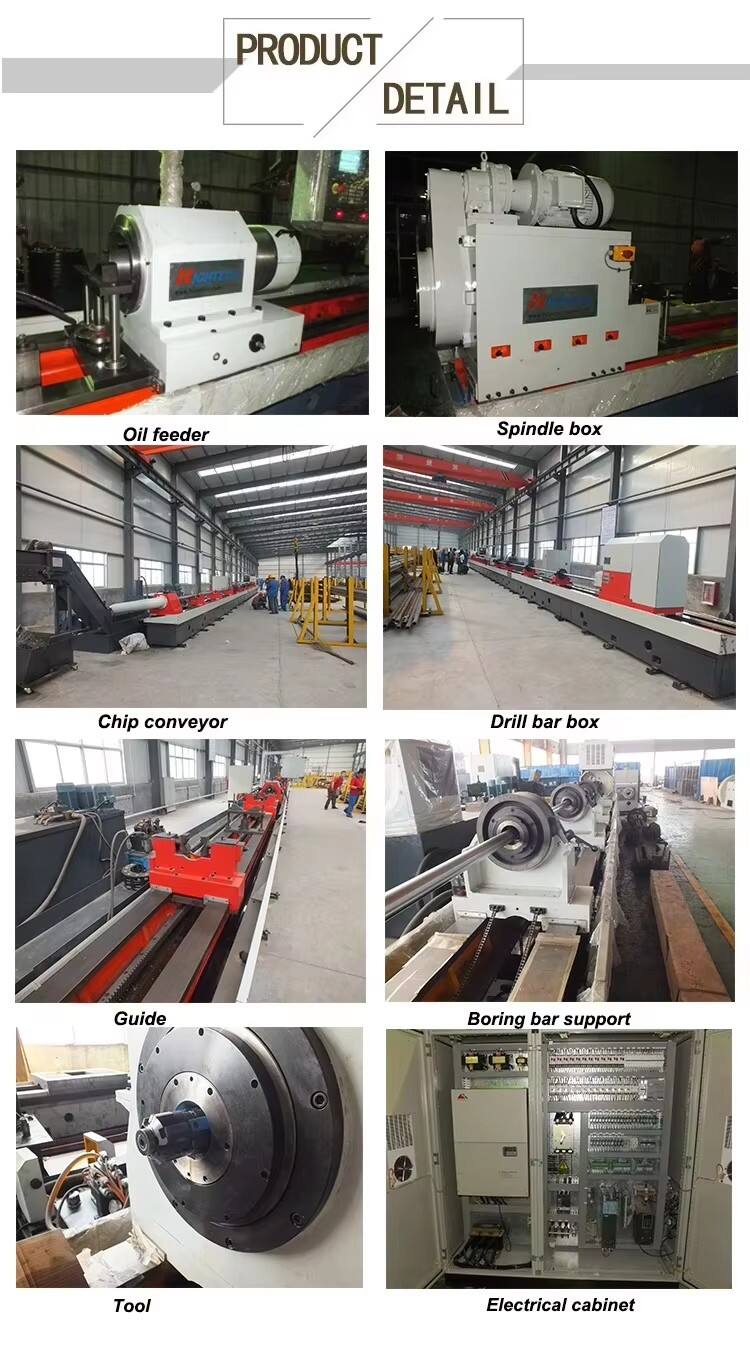

- اجزای اصلی: PLC، موتور، بلبرینگ، موتور، دنده، مخزن تحت فشار، پمپ

- Cnc یا نه: CNC

ولتاژ: 380 ولت 50 هرتز

- وزن (کیلوگرم): 5000

- گارانتی: 1 سال

- بازرسی خروجی ویدئو: ارائه شده است

- گزارش تست ماشین آلات: ارائه شده است

- محل مبدا: جیانگ سو، چین

- نام تجاری: Chuangyuan

ابعاد: اندازه واقعی ماشین

- نکات کلیدی فروش: عمر طولانی

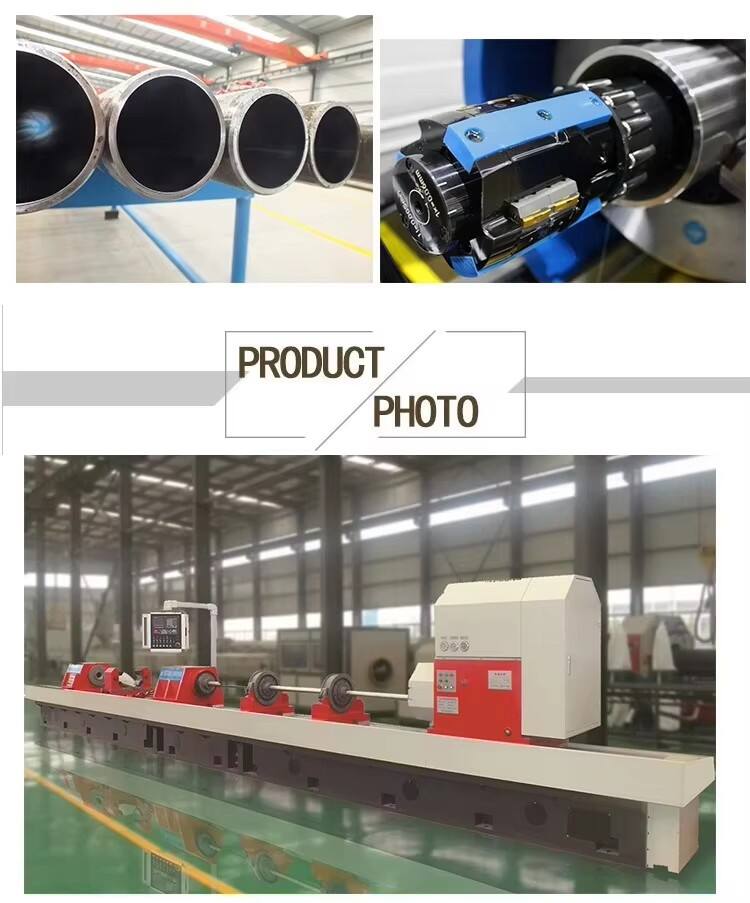

- نام محصول: دستگاه غلتک اسکیتینگ cnc TGK20x2

- کلیدواژه: دستگاه اسکیو و غلتک سوز

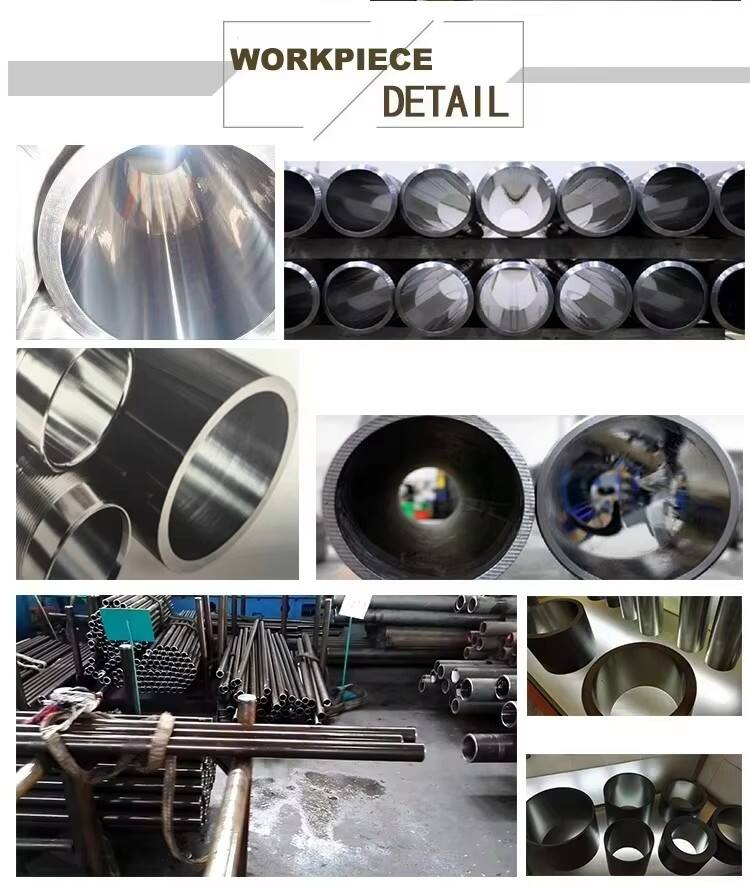

- عرض قطر پردازش: 40-150mm

ویژگیهای کلیدی

ویژگی های خاص صنعت

| قدرت (کیلووات) | 15 |

ویژگیهای دیگر

| اجزای اصلی | PLC، موتور، بلبرینگ، موتور، دنده، مخزن تحت فشار، پمپ |

| CNC یا نه | CNC |

| ولتاژ | 380v 50 هرتز |

| وزن (کیلوگرم) | 5000 |

| ضمانت | 1 سال |

| ویدیو بررسی خروجی | ارائه شده |

| گزارش آزمون ماشینآلات | ارائه شده |

| مکان اصلی | جیانگسو، چین |

| نام برند | چوانگیوان |

| ابعاد (طول*عرض*ارتفاع) | اندازه واقعی ماشین |

| نقاط قوت فروش | عمر طولانی |

| نام محصول | دستگاه غلتک سنگزنی cnc TGK20x2 |

| کلمه کلیدی | دستگاه اسکیو و رول سوز |

| محدوده قطر پردازش | 40 تا 150 میلی متر |

| حداکثر عمق پردازش | 2000 میلیمتر |

| سیستم CNC | زیمنس 808 |

| جعبه میله کسل کننده موتور اصلی | 45KW |

| محدوده سرعت تغذیه | 5-2000mm/min (بدون گام) |

| رنگ | اختیاری |

| عرض مسیر ماشین | 650میلیمتر |

| ارتفاع مرکز پیچ | ۳۵۰ میلیمتر |

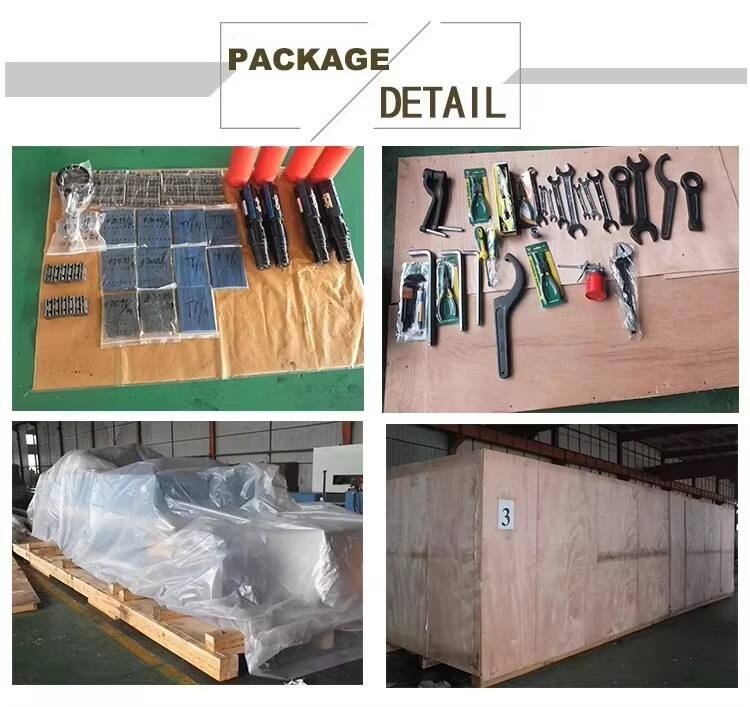

بستهبندی و تحویل

| واحدهای فروش: | مورد تکی |

| اندازه بسته تکی: | 1220X370X230 سانتی متر |

| وزن ناخالص تکی: | 5000000 کیلوگرم |

دستگاه سنگ زنی لوله های سوراخ عمیق و رولر

TGK سری CNC کنده و ماشین tumbling روش پردازش قطعه کار ثابت و ابزار چرخش تغذیه را اتخاذ می کند. ابزار ماشین می تواند پردازش سوراخ داخلی قطعه کار را با تکنولوژی پردازش ساده و دقت بالا از محصولات پردازش شده درک کند. مزایای اصلی دستگاه ابزار بهره وری پردازش بالا، عملکرد پایدار و بهره وری 5-10 برابر از دستگاه حفاری سوراخ عمیق سنتی و ابزار ماشین سوراخ عمیق است؛ درجه کنترل هوشمند بالا است و کنترل دیجیتال و نظارت بر هر دستور عمل دستگاه ابزار ساده و آسان است.

|

آیتم

|

پارامتر

|

|

محدوده قطر پردازش

|

Φ40-φ250mm

|

|

حداکثر عمق پردازش

|

4000 میلیمتر

|

|

عرض مسیر ماشین

|

650میلیمتر

|

|

ارتفاع مرکز پیچ

|

۳۵۰ میلیمتر

|

|

محدوده سرعت چرخش اسپندل و مراحل

|

3~1000r/min (4 گیره، بدون گام)

|

|

موتور اصلی

|

45kW ((موتر فرکانس متغیر AC)

|

|

سیستم CNC

|

زیمنس 808

|

|

محدوده سرعت تغذیه

|

5-2000mm/min (بدون گام)

|

|

سرعت حرکت سریع محموله

|

۳۰۰۰ میلی متر/دقیقه

|

|

محدوده قطر قطعات کاری

|

Φ50~Φ280mm

|

|

موتور تغذیه

|

5.5 کیلووات (سرو موتور AC)

|

|

موتور پمپ خنک کننده

|

گروه های 7.5KW 2 گروه های 5.5KW 2

|

|

موتور پمپ هیدرولیک

|

1.5kW، n=1440r/min

|

|

فشار نامی سیستم خنک کننده

|

2.5 مگا پاسکال

|

|

جریان سیستم خنک کننده

|

200L/min،300L/min،300L/min

|

|

فشار نامی سیستم هیدرولیک

|

6.3Mpa

|

س: آیا شما سازنده هستید؟

A: بله، ما تولید کنندگان خطوط برش به طول هستیم، ما تیم فنی خود را داریم و کارگاه حدود 80000 متر مربع، خوش آمدید از ما دیدن کنید!

س: چه شرایط پرداختی را می پذیرید؟

A: ما در شرایط پرداخت انعطاف پذیر هستیم، همچنین می توانیم در تامین مالی به شما کمک کنیم، لطفا برای جزئیات با ما تماس بگیرید!

س: برای ارائه پیشنهاد به چه اطلاعاتی نیاز دارید؟

A: وزن سیم پیچ، عرض سیم پیچ، ضخامت سیم پیچ، مواد سیم پیچ، حداکثر. طول برش، سرعت برش و نیازهای خاص شما.

س: برای راه اندازی یک کسب و کار جدید چه باید بکنم؟

A: لطفا بلافاصله با ما تماس بگیرید، ما خدمات مشاوره رایگان پیش فروش را ارائه می دهیم. همچنین ما می توانیم به شما در حل آموزش کارگر کمک کنیم.

س: آیا آموزش و نگهداری ارائه می دهید؟

ج: بله. به منظور بهره وری بیشتر شما برای تولید، زمانی که دستگاه به بندر وارد کننده رسید.

شرکت ما مهندسین را برای نصب ماشین می فرستد و مسئول آموزش کارگر مشتری تا زمانی که بتوانند ماشین را به صورت ماهرانه کار کنند.

در طول مدت گارانتی، اگر دستگاه نتواند به طور معمول کار کند، پس از دریافت اخطار شما، ظرف 24 ساعت، مهندسان را برای پردازش به کارخانه شما می فرستیم. اگر آسیب مصنوعی است، پس باید هزینه پرداخت کنید.

هر ماشيني که از کارخانه خارج ميشه همراه با دستورالعمل هاي مربوطه به زبان انگليسي از جمله راهنماي نگهداري و راهنماي کار خواهد بود.

س: چرا شما را انتخاب می کنید؟ تفاوت بین شما و سایر تامین کنندگان چینی چیست؟

A: ما بیش از 20 سال در این زمینه تخصص داشته ایم. خط برش به طول ما به بسیاری از کشورهای جهان صادر می شود. با همان قیمت می توانید محصول با کیفیت بالاتر و خدمات حرفه ای بهتر را از هایتک دریافت کنید.