- पावर (किलोवाट): 15

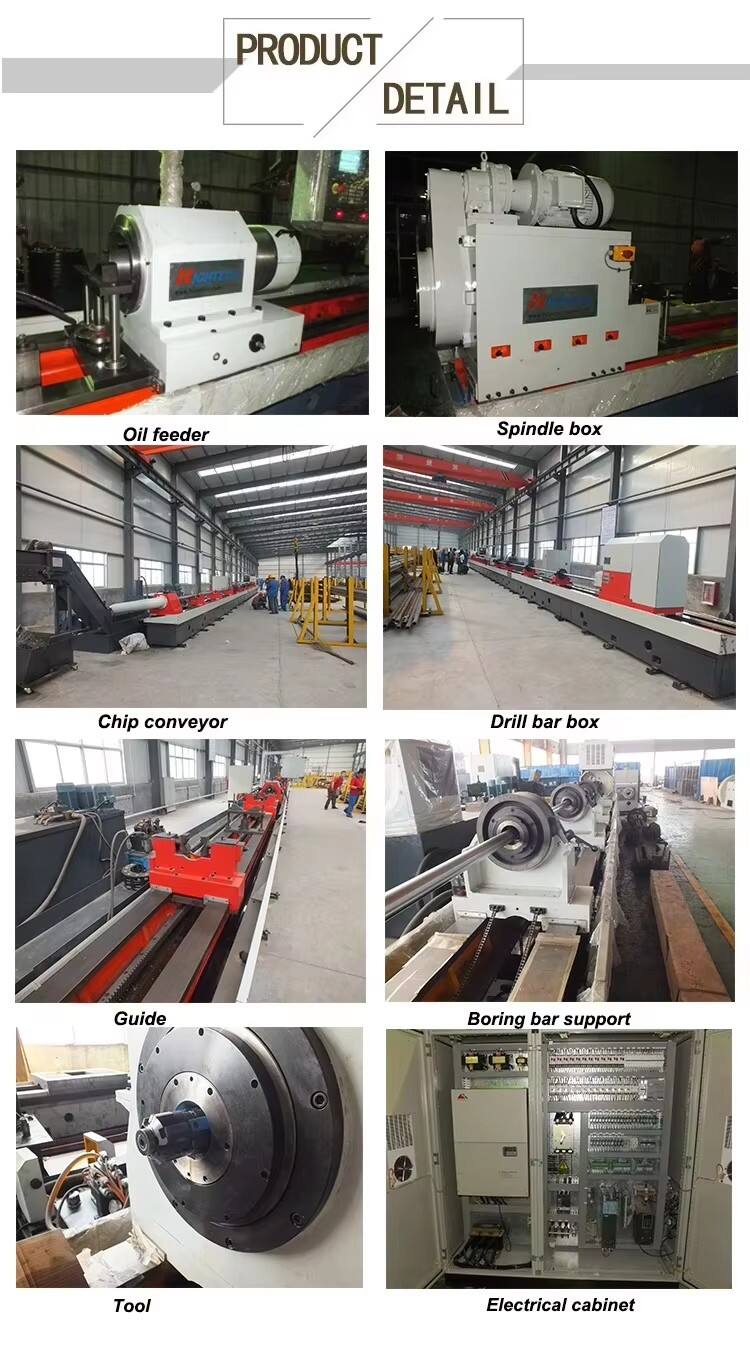

- मुख्य घटक: पीएलसी, इंजन, बेयरिंग, मोटर, गियर, प्रेशर वेसल, पंप

- सीएनसी या नहीं: सीएनसी

- वोल्टेज: 380v 50 hz

- वजन (किलोग्राम): 5000

- 1 साल की वॉरंटी

- वीडियो आउटगोइंग-निरीक्षण: उपलब्ध

- मशीनरी परीक्षण रिपोर्ट: उपलब्ध कराई गई

- उत्पत्ति स्थान: जियांग्सू, चीन

- ब्रांड नाम: चुआंगयुआन

- आयाम(l*w*h): मशीन का वास्तविक आकार

- मुख्य विक्रय बिंदु: लंबी सेवा अवधि

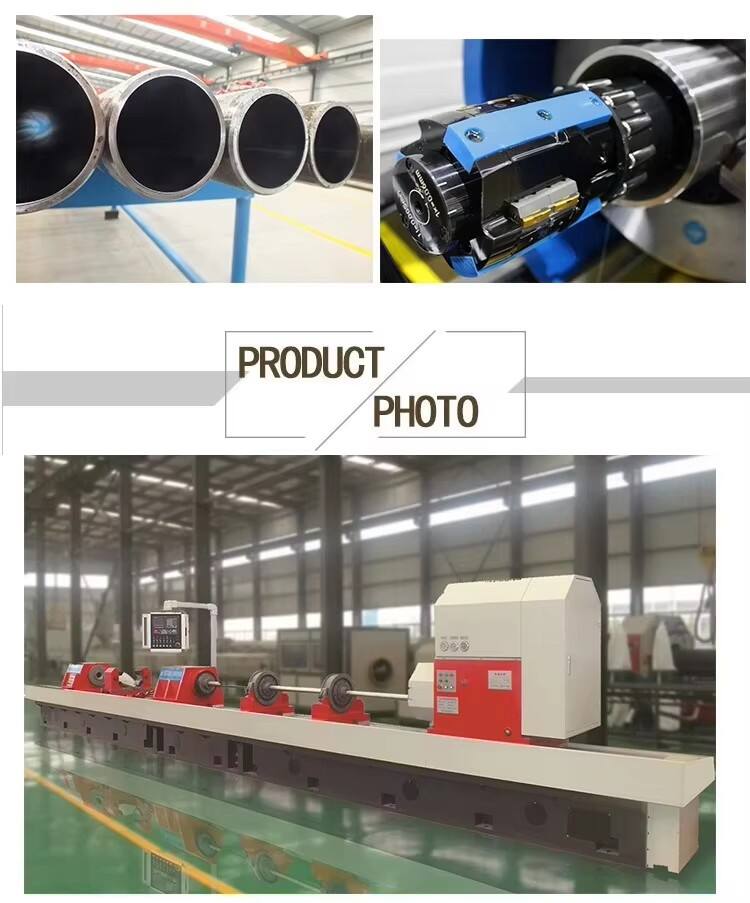

- उत्पाद का नाम: TGK20x2 सीएनसी स्किविंग रोलर बर्निशिंग मशीन

- कीवर्ड: स्काइविंग और रोलर बर्निशिंग मशीन

- प्रोसेसिंग व्यास रेंज: 40-150mm

प्रमुख विशेषताएँ

उद्योग-विशिष्ट गुण

| शक्ति (किलोवाट) | 15 |

अन्य विशेषताएँ

| मुख्य घटक | पीएलसी, इंजन, बेयरिंग, मोटर, गियर, प्रेशर वेसल, पंप |

| सीएनसी या नहीं | सीएनसी |

| वोल्टेज | 380V 50 हर्ट्ज |

| वजन (किग्रा) | 5000 |

| वारंटी | 1 वर्ष |

| वीडियो आउटगोइंग-निरीक्षण | प्रदान किया गया |

| मशीनरी परीक्षण रिपोर्ट | प्रदान किया गया |

| उत्पत्ति का स्थान | जिआंगसू, चीन |

| ब्रांड नाम | च्वांगयुआन |

| आयाम (एल*डब्ल्यू*एच) | मशीन का वास्तविक आकार |

| प्रमुख बिक्री बिंदु | लंबी सेवा जीवन |

| उत्पाद नाम | TGK20x2 सीएनसी स्किविंग रोलर बर्निशिंग मशीन |

| कीवर्ड | स्किविंग और रोलर बर्निशिंग मशीन |

| प्रसंस्करण व्यास रेंज | 40-150 मिमी |

| अधिकतम प्रसंस्करण गहराई | 2000 मिमी |

| CNC प्रणाली | SIEMENS 808 |

| बोरिंग बार बॉक्स मुख्य मोटर | 45 किलोवाट |

| फीडिंग स्पीड रेंज | 5-2000 मिमी/मिनट (स्टेपलेस) |

| रंग | वैकल्पिक |

| मशीन गाइडवे चौड़ाई | 650MM |

| स्पिंडल केंद्र ऊँचाई | 350मिमी |

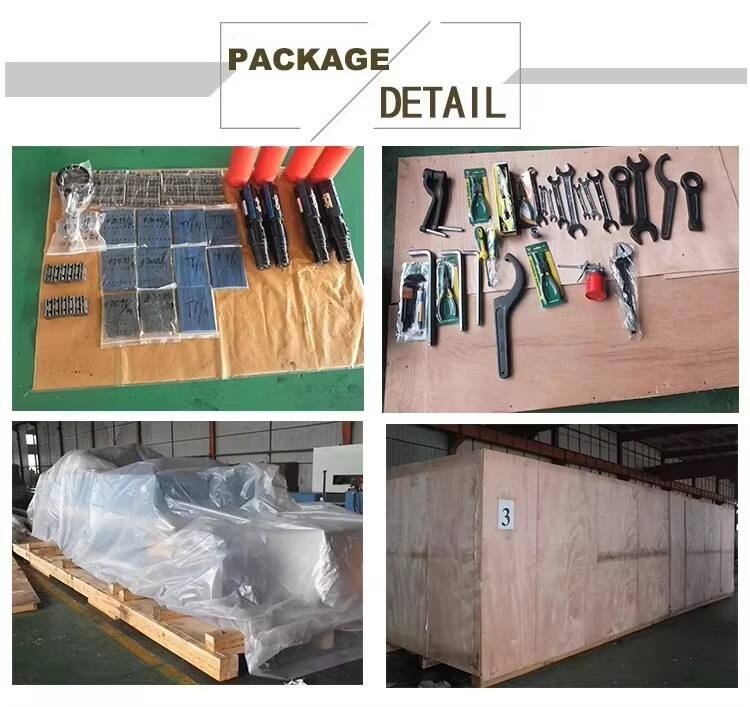

पैकेजिंग और डिलीवरी

| बिक्री इकाइयाँ: | एकल आइटम |

| एकल पैकेज आकार: | 1220X370X230 सेमी |

| एकल कुल वजन: | 5000.000 किलोग्राम |

गहरे छिद्र पाइप स्काइविंग और रोलर बर्निशिंग मशीन

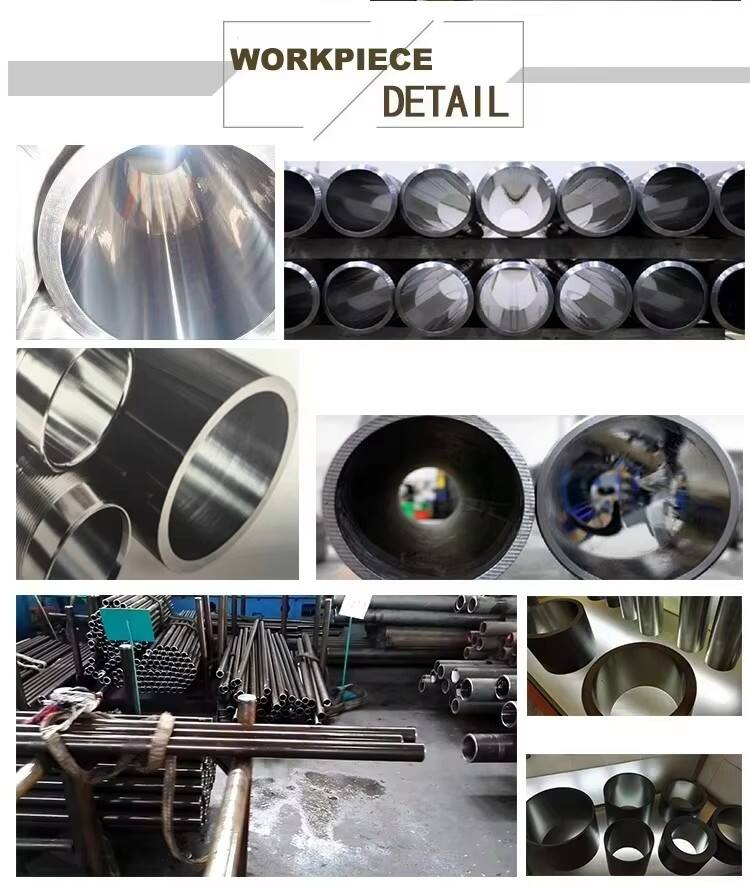

TGK श्रृंखला CNC स्क्रैपिंग और टम्बलिंग मशीन स्थिर कार्यपीस और उपकरण घूर्णन फीड की प्रसंस्करण विधि को अपनाती है। मशीन टूल कार्यपीस के आंतरिक छिद्र की बोरिंग, स्क्रैपिंग और रोलिंग प्रसंस्करण को साकार कर सकता है, जिसमें सरल प्रसंस्करण तकनीक और प्रसंस्कृत उत्पादों की उच्च सटीकता है। मशीन टूल के मुख्य लाभ उच्च प्रसंस्करण दक्षता, स्थिर प्रदर्शन हैं, और इसकी दक्षता पारंपरिक गहरे छिद्र बोरिंग मशीन और गहरे छिद्र मजबूत होनिंग मशीन टूल की तुलना में 5-10 गुना है; बुद्धिमान नियंत्रण की डिग्री उच्च है, और मशीन टूल के प्रत्येक क्रिया आदेश का डिजिटल नियंत्रण और निगरानी सरल और संचालित करने में आसान है।

|

आइटम

|

पैरामीटर

|

|

प्रसंस्करण व्यास रेंज

|

Φ40-φ250mm

|

|

अधिकतम प्रसंस्करण गहराई

|

4000 मिमी

|

|

मशीन गाइडवे चौड़ाई

|

650MM

|

|

स्पिंडल केंद्र ऊँचाई

|

350मिमी

|

|

स्पिंडल घूर्णन गति सीमा और चरण

|

3~1000r/min (4 गियर्स, स्टेपलेस)

|

|

मुख्य मोटर

|

45kW(AC वेरिएबल फ्रीक्वेंसी मोटर)

|

|

CNC प्रणाली

|

SIEMENS 808

|

|

फीडिंग स्पीड रेंज

|

5-2000mm/min (स्टेपलेस)

|

|

कैरिज तेजी से चलने की गति

|

3000mm/min

|

|

क्लैंपिंग कार्यपीस व्यास सीमा

|

Φ50~Φ280mm

|

|

फीडिंग मोटर

|

5.5 किलोवाट (एसी सर्वो मोटर)

|

|

शीतलन पंप मोटर

|

7.5KW 2 समूह 5.5KW 2 समूह

|

|

हाइड्रोलिक पंप मोटर

|

1.5kW, n=1440r/min

|

|

कूलिंग सिस्टम रेटेड प्रेशर

|

2.5Mpa

|

|

कूलिंग सिस्टम फ्लो

|

200L/min,300L/min, 300L/min

|

|

हाइड्रोलिक सिस्टम रेटेड प्रेशर

|

6.3Mpa

|

प्रश्न: क्या आप निर्माता हैं?

एक: हाँ, हम लंबाई लाइन में कटौती के निर्माता हैं, हम अपनी तकनीकी टीम है, और लगभग 80,000 वर्ग मीटर कार्यशाला, हमें यात्रा करने के लिए आपका स्वागत है!

प्रश्न: आप कौन सी भुगतान शर्तें स्वीकार करते हैं?

एक: हम भुगतान शर्तों पर लचीले हैं, हम वित्तपोषण पर भी आपकी मदद कर सकते हैं, कृपया जानकारी के लिए हमसे संपर्क करें!

प्रश्न: प्रस्ताव बनाने के लिए आपको किस जानकारी की आवश्यकता होगी?

एक: कुंडल वजन, कुंडल चौड़ाई, कुंडल मोटाई, कुंडल सामग्री, अधिकतम काटने की लंबाई, काटने की गति और आपकी विशेष आवश्यकताएं।

प्रश्न: नया व्यवसाय शुरू करने के लिए मुझे क्या करना चाहिए?

ए: कृपया हमसे तुरंत संपर्क करें, हम मुफ्त प्री-सेल्स कंसल्टेंट सेवा प्रदान करते हैं। इसके अलावा हम आपको कार्यकर्ता प्रशिक्षण को हल करने में मदद कर सकते हैं।

प्रश्न: क्या आप प्रशिक्षण और रखरखाव प्रदान करते हैं?

उत्तर: हाँ। उत्पादन के लिए आपकी अधिक दक्षता के लिए, जब मशीन आयातक के बंदरगाह पर आ गई है।

हमारी कंपनी मशीन स्थापित करने के लिए इंजीनियरों को भेजेगी और ग्राहक के कार्यकर्ता को प्रशिक्षित करने के लिए जिम्मेदार होगी जब तक कि वे मशीन को कुशलतापूर्वक संचालित नहीं कर सकते।

वारंटी समय के दौरान, यदि डिवाइस सामान्य रूप से काम नहीं कर सकता है, तो आपकी सूचना प्राप्त करने के बाद, 24 घंटे के भीतर, हम प्रसंस्करण के लिए आपके कारखाने में इंजीनियरों को भेज देंगे; अगर यह कृत्रिम क्षति है, तो लागत चार्ज करने की आवश्यकता है।

फैक्ट्री से निकलने वाली प्रत्येक मशीन संबंधित अंग्रेजी निर्देशों के साथ होगी जिसमें रखरखाव मैनुअल और संचालन मैनुअल शामिल हैं।

प्रश्न: आपको क्यों चुना? आपके और अन्य चीनी आपूर्तिकर्ता के बीच क्या अंतर है?

उत्तर: हम इस क्षेत्र में 20 से अधिक वर्षों से विशेषज्ञता रखते हैं। हमारी कट टू लेंथ लाइन दुनिया के कई देशों में निर्यात की जाती है। आप हाईटेक से उसी कीमत पर उच्च गुणवत्ता वाले उत्पाद और बेहतर पेशेवर सेवा प्राप्त कर सकते हैं।