- Vermogen (kw): 15

- Kerncomponenten: PLC, motor, lager, elektromotor, tandwiel, drukvat, pomp

- CNC of niet: CNC

- Spanning: 380220/415/440V

- Gewicht (kg): 5000

- Garantie: 1 jaar

- Video-uitgaande inspectie: Verstrekt

- Machinetestrapport: Verstrekt

- Plaats van herkomst: Jiangsu, China

- Merknaam: Chuangyuan

- Afmetingen(l*b*h): 12100*3600*2200mm

- Belangrijkste verkoopargumenten: Lange levensduur

- Productnaam: TGK20x2 cnc skiving roller polijstmachine

- Trefwoord: Skiving- en rolpolijstmachine

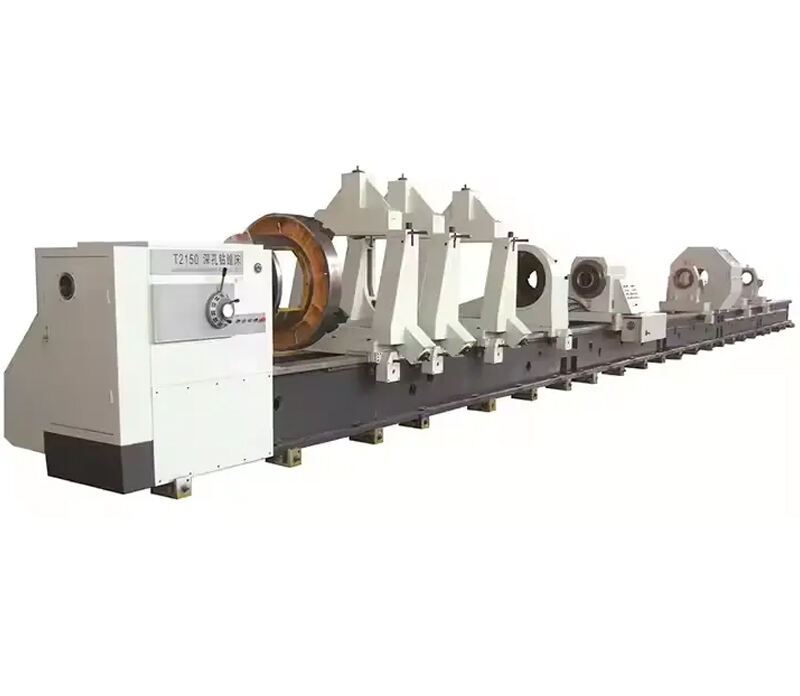

- Productnaam: Horizontale Diepe Gat CNC Cilinder Honingmachine voor Hydraulische Buizen

Sleutelattributen

Branchspecifieke kenmerken

| Vermogen (KW) | 15 |

Andere kenmerken

| Kerncomponenten | plc, motor, lager, motor, tandwiel, drukvat, pomp |

| Cnc of niet | CNC-machines |

| Spanning | 380220/415/440V |

| Gewicht (kg) | 5000 |

| Garantie | 1 JAAR |

| Video uitgaande inspectie | Geleverd |

| Machinerapport | Geleverd |

| Plaats van Herkomst | Jiangsu, china |

| Merkennaam | ChuangYuan |

| Afmetingen(L*B*H) | 12100*3600*2200 mm |

| belangrijkste verkoopargumenten | Lange levensduur |

| Productnaam | TGK20x2 cnc-schaafrolpolijstmachine |

| Trefwoord | Machine voor het schaven en rollen van de slijpsteen |

| Productnaam | Horizontale diepgat CNC-cilinder-afschlipsmachine voor hydraulische buizen |

| De diameter van het slijpgat | 40-500 mm |

| Maximale slijpdiepte | 6000mm |

| Diameters van het werkstuk | 50-600 mm |

| De waarde van de waarde van de waarde van de waarde van de waarde van de waarde van de waarde van de waarde van de waarde van de waarde van de waarde van de waarde van de waarde van de waarde van de waarde van de waarde van de waarde van de waarde van de waarde van de waarde van de waarde van de waarde van de waarde van de waarde van de waarde van de waarde van | 500mm |

| De snelheid van de spindel van de slijpstaaf | 10-350 r/min (stapsloze regeling) |

| Versnellingsbereik van het wagen | 1-28 m/min (stapsloze regeling) |

| Vermogen van de motor van de slijpmachine | 15kW |

| Veranderende motorkracht | 5,5 kW (wisselstroomservomotor) |

| Maaikop die de motorvermogen uitbreidt | 0,75 kW (AC servomotor) |

Verpakking en verzending

| Verkoopseenheden: | Enkel item |

| Enkele pakketgrootte: | 1220X370X230cm |

| Enkel nettogewicht: | 5000.000kg |

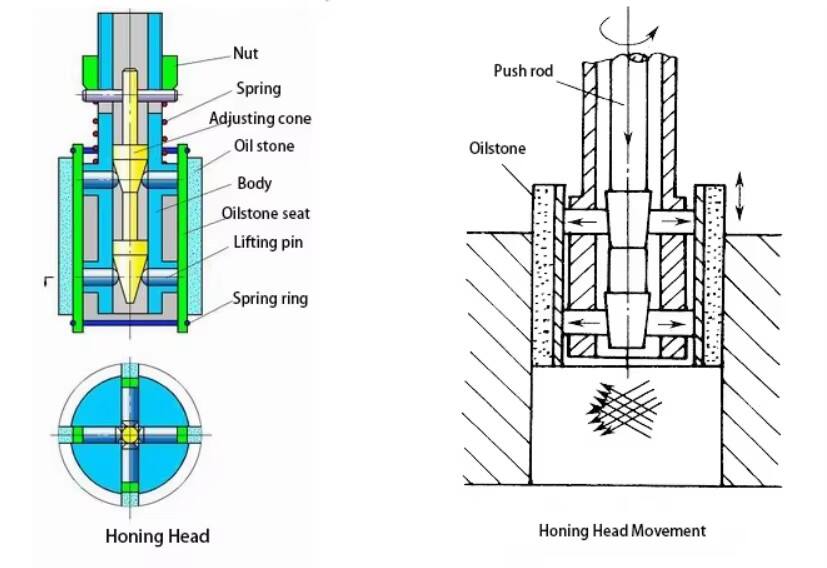

CNC Diepe Gat Buis Honingmachine

Deze diepgat slijpmachine is gespecialiseerd in het verwerken van cilindrische diepgatonderdelen.

De inbreng van de olie wordt door een olievoerder geleverd, de olie stroomt door het snijgebied en brengt de chips (die zich in de boorstaaf bevinden) naar de achterste vervoerder van de machine.

Bij het boren gebruikt het een drukborremethode, de olievoervoerder levert olie, de koelvloeistof brengt de chips naar de kop van de machine.

Deze machine kan ook worden uitgerust met een hydraulische harmonomegathus-afschleuren kop.

De machine heeft een hydraulisch systeem, een koelsysteem en een chipverwijderingssysteem.

|

Nee

|

Artikel

|

Parameter

|

|

1

|

De diameter van de slijpplaat

|

Φ60~200 mm

|

|

2

|

Centrumhoogte

|

400mm

|

|

3

|

Procesdiepte

|

600 tot 8000 mm

|

|

4

|

3 keer de diameter van de kaak

|

Φ500 mm

|

|

5

|

Klembereik van de middelste rugleuning

|

Φ50~400 mm

|

|

6

|

Hoofdmotor

|

De Commissie heeft de Commissie verzocht de volgende gegevens te verstrekken:

|

|

7

|

Spindelsnelheid

|

50 tot 800 t/min, 12 soorten

|

|

8

|

motor voor een barbox

|

De Commissie heeft de Commissie verzocht de volgende gegevens te verstrekken:

|

|

9

|

De snelheid van de spindel van de boorbal

|

50 tot 400 t/min, 12 soorten

|

|

10

|

Voedingsnelheid

|

5~5000 mm/min ((stapsloos)

|

|

11

|

CNC-systeem

|

SIEMENS 808D

|

|

12

|

Voedingsmotor

|

40 N.M., SIEMENES servomotor

|

|

13

|

motor voor olievoeding

|

32 N.M,CTB-servomotor

|

|

14

|

Koelpomp motor

|

De in punt 5.4.1 bedoelde verwarming moet worden uitgevoerd op een temperatuur van ± 5 °C.

|

|

15

|

Nominale druk van koelsysteem

|

2,5 MPa

|

|

16

|

De koelsysteemstroom

|

100,200,300,400 l/min

|

|

17

|

Volume koeltank

|

4000 liter

|

|

18

|

Koelpompstroom van het slijpen

|

50 l/min

|

|

19

|

Koelvatvolume van het slijpen

|

andere

|

Q: Bent u een fabrikant?

A: Ja, wij zijn fabrikant van op maat gesneden producten. Wij beschikken over een eigen technisch team en een werkplaats van ongeveer 80.000 m². U bent van harte welkom om ons te bezoeken!

V: Welke betalingsvoorwaarden accepteert u?

A: Wij zijn flexibel wat betreft betalingsvoorwaarden en kunnen u ook helpen met financiering. Neem contact met ons op voor meer informatie!

V: Welke informatie heeft u nodig om het voorstel te doen?

A: Gewicht van de spoel, breedte van de spoel, dikte van de spoel, materiaal van de spoel, maximale snijlengte, snijsnelheid en uw speciale vereisten.

V: Wat moet ik doen om een nieuw bedrijf te starten?

A: Neem direct contact met ons op, wij bieden gratis pre-sales consultant service. Ook kunnen wij u helpen met het oplossen van de werknemerstraining.

V: Bieden jullie ook training en onderhoud aan?

A: Ja. Om uw productie efficiënter te maken, wanneer de machine is aangekomen in de haven van de importeur.

Ons bedrijf stuurt technici om de machine te installeren en is verantwoordelijk voor het opleiden van de werknemers van de klant, totdat zij de machine vakkundig kunnen bedienen.

Als het apparaat binnen de garantieperiode niet normaal werkt, sturen we binnen 24 uur na ontvangst van uw melding technici naar uw fabriek om het te laten repareren. Als er sprake is van kunstmatige schade, moeten we kosten in rekening brengen.

Elke machine die het fabriek verlaat zal gepaard gaan met bijbehorende Engelse instructies, inclusief onderhoudshandleiding en bedieningshandleiding.

V: Waarom zou ik voor u kiezen? Wat is het verschil tussen u en andere Chinese leveranciers?

A: Wij zijn al meer dan 20 jaar gespecialiseerd in dit gebied. Onze cut-to-length lijn wordt geëxporteerd naar veel landen in de wereld. U kunt hogere kwaliteit producten en betere professionele service krijgen van Hitech voor dezelfde prijs.

Fabriek Groothandel DS703A CNC EDM Kleine Gat Boormachine edm Super Boormachine

Staalrol op lengte gesneden lijn voor het richten en snijden van staalrol

Bewerkingscentrum 5-assige bewegende kolom portaalbewerkingsfreescentrum Automatisch gereedschap

Hoge nauwkeurigheid Gatboormachine Horizontale Diepe Gatboor- en Boormachine TK2120