- Spanning: 220V/380V/415V

- Nominaal vermogen: 30KW/40HP;37KW/50HP

- Kerncomponenten: PLC, motor, Versnellingsbak, Drukvat, Tandwiel, Pomp

- Garantie: 1 jaar

- Gewicht (kg): 3000

- Plaats van herkomst: Jiangsu, China

- Herhaalbaarheid (x/y/z) (mm): ±0.025

- Tafelverplaatsing (x) (mm): 3000

- Tafelverplaatsing (y) (mm): 1500

- Tafelverplaatsing (z) (mm): 200

- Aantal assen: 3

- Video-uitgaande inspectie: Verstrekt

- Machinetestrapport: Verstrekt

- Snijnauwkeurigheid (mm): ±0.1

- Merknaam: Chuangyuan

Sleutelattributen

Branchspecifieke kenmerken

| Spanning | 220v/380v/415v |

| Genomineerd vermogen | 30 kW/40 pk; 37 kW/50 pk |

Andere kenmerken

| Kerncomponenten | PLC, motor, versnellingsbak, drukvat, versnellingsbak, pomp |

| Garantie | 1 JAAR |

| Gewicht (kg) | 3000 |

| Plaats van Herkomst | Jiangsu, china |

| herhaalbaarheid (x/y/z) (mm) | ± 0,025 |

| tafelbeweging (x) (mm) | 3000 |

| tafelbeweging (j) (mm) | 1500 |

| tafelbeweging (z) (mm) | 200 |

| aantal assen | 3 |

| Video uitgaande inspectie | Geleverd |

| Machinerapport | Geleverd |

| Snijnauwkeurigheid ((mm) | ±0,1 |

| Merkennaam | ChuangYuan |

| Afmetingen(L*B*H) | Volgens het model van de machine |

| belangrijkste verkoopargumenten | Lange levensduur |

| Naam | Waterstraal snijtafel van waterstraal snijmachine snijmachine |

| Snijmaterialen | Steen, plastic, roestvrij staal, messing, aluminium, glas, enz. |

| Snijnauwkeurigheid | +/- 0,1 mm |

| Max.stroompercentage | 3,7 L/min |

| Aandrijfsysteem | AC servo en schroef, geleidingsrail |

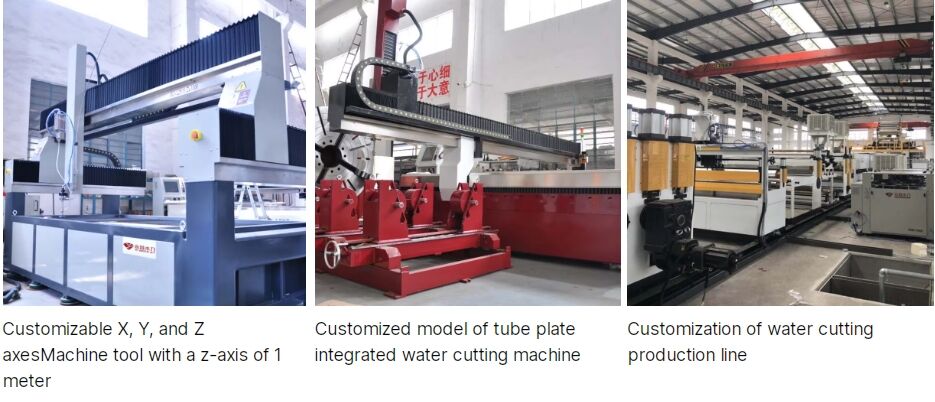

| Grootte | op maat gemaakt |

| structuur | Buizen- of kantelkracht |

| Kleur | wit en rood of op maat |

| Werkdruk | 320-400mpa |

| Abrasive naam | granaten |

Als geavanceerde snijmachine heeft de waterstraal snijmachine een breed scala aan toepassingen op industrieel gebied.

Een complete set waterstraal-snijmachines bestaat gewoonlijk uit vijf hoofdonderdelen:

De eerste is het hogedruksysteem, dat essentieel is voor het genereren van een hogedrukwaterafvoer en een sterke krachtondersteuning biedt voor het snijden;

De tweede is het snijplatform, dat het te snijden materiaal draagt en een stabiele basis biedt voor de snijoperatie;

Het derde is het besturingssysteem, net als het intelligente centrum van de apparatuur, dat verschillende parameters van het gehele snijproces nauwkeurig reguleert;

Het vierde is het koelsysteem, dat de temperatuur tijdens de werking van de apparatuur effectief verlaagt om de stabiliteit en veiligheid van de apparatuur te waarborgen.

Het koelsysteem omvat luchtkoeling en waterkoeling, en het is noodzakelijk om de apparatuur met een hoge of lage koelintensiviteit redelijkerwijs te kiezen volgens verschillende gebruikstemperatuuromgevingen om zich aan te passen aan de specifieke eisen van de werkomstandigheden; het vijfde is het zandtoevoerstelsel, dat een belangrijke

Het zand dat wij gebruiken is gewoonlijk 80-maas granaten zand, dat een goede snijprestatie en stabiliteit heeft.

Hoe is ons YC waterjet snijplatform gemaakt?

waterstraal snijkop

Ultrahoogdrukwaterstraal is voornamelijk onderverdeeld in slijpwerk en alleen waterwerk ((Ook zuiver waterwerk).

Daarom is de snijkop ook onderverdeeld in een snijkop met waterstraal en een snijkop met waterstraal.

* Schurend waterstraalsnijden wordt voornamelijk gebruikt voor het snijden van metaal (zoals koolstofstaal, roestvrij staal, enz.), non-ferro metalen (zoals koper, aluminium, titaniumlegering, magnesiumlegering, enz.), steen, glas, grote dikte composietmaterialen (zoals koolstofvezel, glasvezel) enzovoort.

* Alleen watersnijden wordt voornamelijk gebruikt voor het snijden van rubber, schuim, stof, papier, steenwol, voedsel (puur waterstraalsnijden) enzovoort.

Welke materialen kan een waterstraal snijden?

Legeringen, staal, laminaat, composiet, plastic/acryl, rubber, bekleding, glasvezel, glas...

Aanpasbare waterstraalsnijsystemen

|

CNC-waterscheepscherm-snijmachine Parameter ((L=Gantry type)

|

|||||||

|

Parameters

|

eenheid

|

De in punt 5.2.2.4 bedoelde vergunningen zijn geldig.

|

De volgende categorieën:

|

De in punt 3.4.1 bedoelde vergunningen zijn geldig.

|

De in punt 3.4.1 bedoelde vergunningen zijn geldig.

|

De in punt 5.2.2.4 bedoelde vergunningen zijn geldig.

|

|

|

Efficiënte snijplaats

|

mm

|

1000 × 1000

|

2000×1500

|

3000 × 1500

|

3000×2000

|

2000 × 6000

|

|

|

Reis door de as |

X

|

mm

|

1000

|

2000

|

3000

|

3000

|

2000

|

|

Y

|

mm

|

1000

|

1500

|

1500

|

2000

|

6000

|

|

|

Z

|

mm

|

150 tot en met 180

|

150 tot en met 180

|

150 tot en met 180

|

150 tot en met 180

|

150 tot en met 180

|

|

|

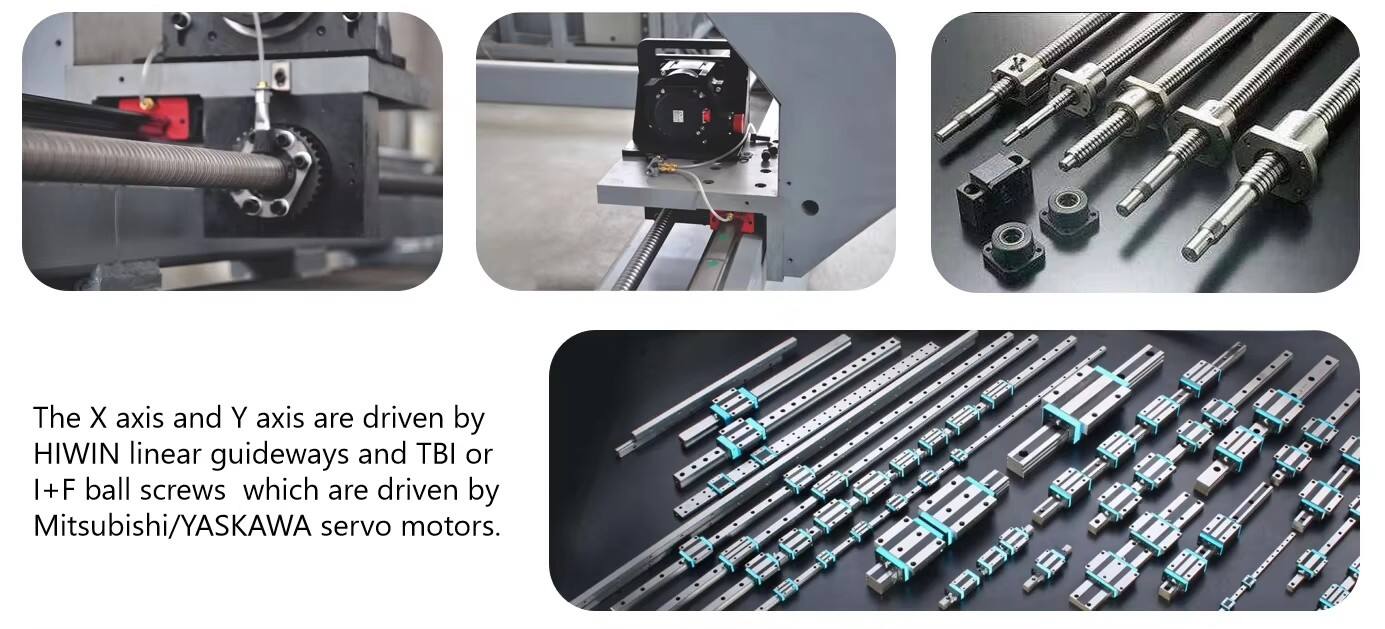

De X-as en de Y-as nemen HIWIN of I+F-balschroef en -leiding aan.

Mitsubishi of Yaskawa. |

|||||||

|

Snijnauwkeurigheid

|

mm

|

±0,1

|

|||||

|

Positioneringsnauwkeurigheid

|

mm

|

± 0,025

|

|||||

|

X,Y Droog-run snelheid

|

m/min

|

0-15 (als 30m/min snelheid nodig is, kunnen we op verzoek doen)

|

|||||

|

Snelheid van Knippen

|

m/min

|

voor detailmateriaal en dikte

|

|||||

V: Wat is het voordeel van waterstraal snijmachine?

A: koudbewerking, geen warmtevervorming; sterke snijvermogen, bijna elk materiaal kan worden gesneden; zuivere waterstraal kan zachte materialen snijden, snijwaterstraal kan harde materialen snijden, zelfs brandbare en explosieve voorwerpen snijden; snijnauwkeurigheid is hoog, rand Waterjet heeft ook de titel van universele snijmachine.

V: Hoe kies ik een standaard snijtafel?

A: U moet de grootte van de materialen die u wilt verwerken of de grootte van de snijtafel aanbieden.

V: Hoe het probleem van de snedehelling op te lossen met 3-assig watersnijden?

A: Het is geen verticale snede voor een waterstraalsnijder. Dit is te wijten aan de fysieke eigenschappen van waterstraal. Als er een nauwkeurige verticale hoeksnede vereist is, zullen we u een vijf-assige dynamische snijsysteem aanbieden. Het kan een kleine hoekcompensatie in de software maken.

V: Is de apparatuur gemakkelijk te bedienen?

A: Gebaseerd op de goede waterjetsoftware, kan de bediener het gemakkelijk leren. en als de klant een nieuwe machine bestelt, zal onze technicus training geven voor het gebruik en onderhoud van de machine.

Bewerkingscentrum 5-assige bewegende kolom portaalbewerkingsfreescentrum Automatisch gereedschap

Fabriek Groothandel DS703A CNC EDM Kleine Gat Boormachine edm Super Boormachine

Staalrol op lengte gesneden lijn voor het richten en snijden van staalrol

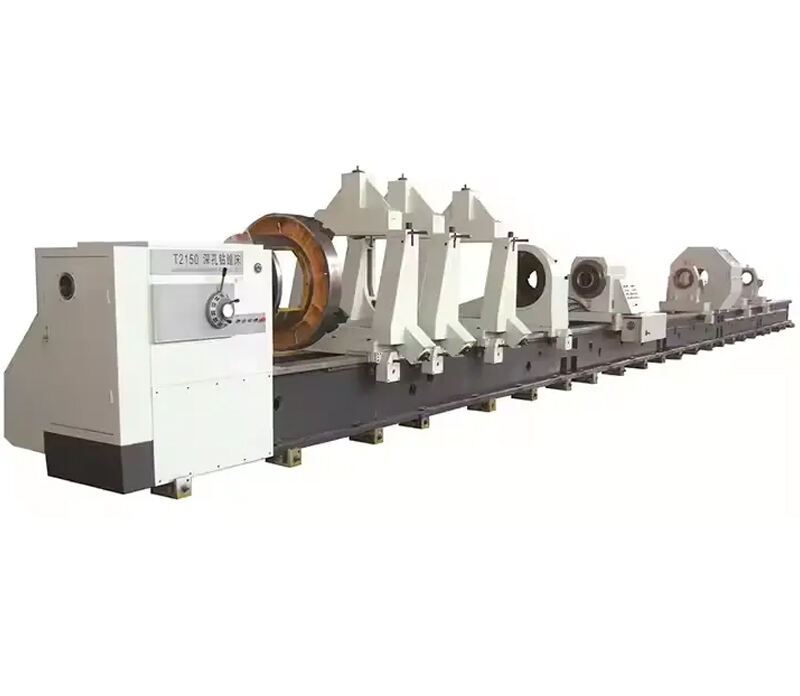

Hoge nauwkeurigheid Gatboormachine Horizontale Diepe Gatboor- en Boormachine TK2120