- โลตติจ: 220V/380V/415V

- พลังงานระดับ: 30KW / 40HP; 37KW / 50HP

- ส่วนประกอบหลัก: PLC, มอเตอร์, กล่องเกียร์, ถังความดัน, เกียร์, ปั๊ม

- การรับประกัน: 1 ปี

- น้ําหนัก (กิโลกรัม): 3000

- แหล่งกำเนิด: มณฑลเจียงซู ประเทศจีน

- ความซ้ํา (x/y/z) (มม): ±0.025

- การเคลื่อนที่ของโต๊ะ (x) (มม.): 3000

- การเคลื่อนที่ของโต๊ะ (y) (มม.): 1500

- การเคลื่อนที่ของโต๊ะ (z) (มม.): 200

- จํานวนแกน: 3

- การตรวจสอบวิดีโอขาออก: มีให้

- รายงานผลการทดสอบเครื่องจักร : มีให้

- ความแม่นยําในการตัด ((มม): ± 0.1

- ชื่อยี่ห้อ: Chuangyuan

คุณสมบัติหลัก

อ性的属性特定于行业

| โลต | 220v/380v/415v |

| พลังงานระดับ | 30KW/40HP; 37KW/50HP |

คุณสมบัติอื่น ๆ

| ส่วนประกอบหลัก | PLC มอเตอร์กล่องเกียร์ เครื่องปั่น เครื่องปั่น |

| การรับประกัน | 1 ปี |

| น้ำหนัก (กก.) | 3000 |

| สถานที่กำเนิด | เจียงซู, จีน |

| ความสามารถในการทำซ้ำ (x/y/z) (มม.) | ± 0.025 |

| ระยะการเดินทางของโต๊ะ (x) (มม.) | 3000 |

| ระยะการเดินทางของโต๊ะ (y) (mm) | 1500 |

| ระยะการเคลื่อนที่ของโต๊ะ (z) (มม.) | 200 |

| จํานวนแกน | 3 |

| วิดีโอการตรวจสอบขาออก | จัดหา |

| รายงานการทดสอบเครื่องจักร | จัดหา |

| ความแม่นยําในการตัด ((มม) | ±0.1 |

| ชื่อแบรนด์ | ชวงหยวน |

| ขนาด (L*W*H) | ตามรุ่นเครื่อง |

| จุดขายหลัก | อายุการใช้งานยาวนาน |

| ชื่อ | โต๊ะตัดน้ําเจ็ตของเครื่องตัดน้ําเจ็ต |

| วัสดุตัด | หิน พลาสติก เหล็กไร้ขัดเหล็ก ทองแดง อลูมิเนียม แก้ว ฯลฯ |

| ความแม่นยําในการตัด | +/- 0.1 มม. |

| อัตราการไหลของน้ําสูงสุด | 3.7 ลิตร/นาที |

| ระบบขับเคลื่อน | AC servo และสกรู, guiderail |

| ขนาด | สร้างตามสั่ง |

| โครงสร้าง | กานท์รี่หรือคานติเลเวอร์ |

| สี<br> | ขาวและแดง หรือตามสั่ง |

| ความดันทำงาน | 320-400mpa |

| ชื่อที่ใช้บด | สีเขียว |

เป็นอุปกรณ์ตัดที่ทันสมัย เครื่องตัดน้ําเจ็ต มีการใช้งานในสาขาอุตสาหกรรมที่กว้างขวาง

ชุดเครื่องตัดน้ําแบบเจ็ตเต็มโดยทั่วไปประกอบด้วย 5 ส่วนหลัก

อันดับแรกคือระบบความดันสูง ซึ่งเป็นกุญแจในการผลิตกระแสน้ําความดันสูง และให้การสนับสนุนพลังงานที่แข็งแรงในการตัด

อันที่สองคือพื้นที่ตัด ซึ่งถือวัสดุที่จะตัด และเป็นพื้นฐานที่มั่นคงสําหรับการตัด

อันที่สามคือระบบควบคุม เหมือนกับศูนย์กลางที่ฉลาดของอุปกรณ์ ปรับปรุงปริมาตรต่างๆ ของกระบวนการตัดทั้งหมดให้ถูกต้อง

ระบบที่สี่คือระบบเย็น ที่ช่วยลดอุณหภูมิภายในการทํางานของอุปกรณ์ เพื่อให้อุปกรณ์มั่นคงและปลอดภัย

ระบบเย็นรวมระบบทําความเย็นด้วยอากาศและระบบทําความเย็นด้วยน้ํา และจําเป็นต้องเลือกอุปกรณ์ที่มีความเข้มแข็งในการทําความเย็นสูงหรือต่ําให้เหมาะสมตามสภาพแวดล้อมอุปกรณ์ที่ใช้งานได้ในอุณหภูมิที่แตกต่างกัน เพื่อปรับตัวให้เหมาะสมกับ

ทรายที่เราใช้มักจะเป็นทรายแกรเนต 80 mesh ที่มีประสิทธิภาพการตัดและความมั่นคงที่ดี

แพลตฟอร์มตัดน้ํา YC ของเราทํายังไง

หัวตัดน้ําเจ็ต

เครื่องฉายน้ําความดันสูงสุด แบ่งเป็นการตัดแบบบดและการตัดเพียงน้ํา ((รวมการตัดน้ําบริสุทธิ์)

ดังนั้นหัวตัดก็แบ่งออกเป็นหัวตัดน้ําเจ็ตแบบหยาบ และหัวตัดน้ําเจ็ตแบบบริสุทธิ์

* การตัดด้วยน้ำเจ็ทขัดผิวใช้ principalmente สำหรับการตัดโลหะ (เช่น เหล็กกล้าคาร์บอน เหล็กกล้าไม่สนิม เป็นต้น) โลหะที่ไม่ใช่เหล็ก (เช่น ทองแดง อลูมิเนียม โลหะผสมไทเทเนียม โลหะผสมแมกนีเซียม เป็นต้น) หิน กระจก วัสดุคอมโพสิตความหนาใหญ่ (เช่น ไฟเบอร์คาร์บอน ไฟเบอร์แก้ว) และอื่นๆ

* การตัดด้วยน้ำอย่างเดียวใช้ principalmente สำหรับการตัดgom โฟม ผ้า กระดาษ ร็อกวูล อาหาร (การตัดด้วยน้ำบริสุทธิ์) และอื่นๆ

วัสดุอะไรที่เครื่องเจ็ตน้ําตัดได้

สายสลัด เหล็ก แลมเนท สารประกอบ พลาสติก/แอคริลิก ยาง ผงผัด ใยแก้ว กระจก...

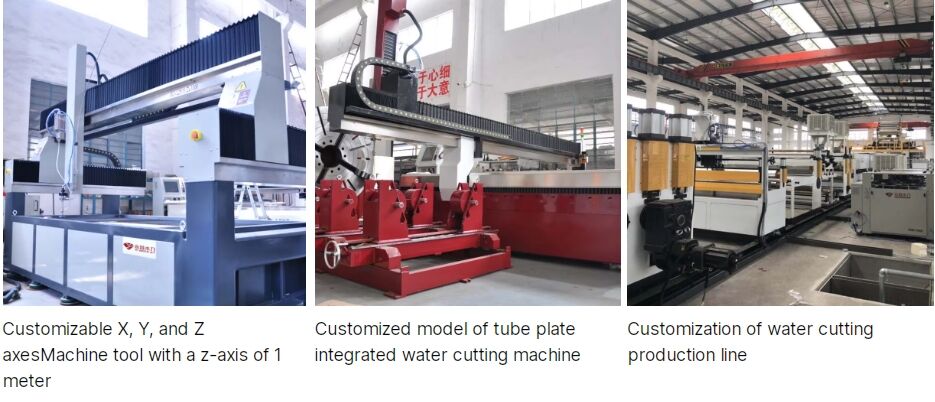

ระบบตัดน้ําแบบปรับแต่ง

|

ปารามิเตอร์เครื่องตัดน้ําแบบ CNC ((L=ชนิดแกนทรี)

|

|||||||

|

พารามิเตอร์

|

หน่วย

|

YCWJ-L1010

|

YCWJ-L2015

|

YCWJ-L3015

|

YCWJ-L3020

|

YCWJ-L2060

|

|

|

พื้นที่ตัดที่ประสิทธิภาพ

|

มม

|

1000 × 1000

|

2000×1500

|

3000 × 1500

|

3000×2000

|

2000×6000

|

|

|

การเดินทางของแกน |

X

|

มม

|

1000

|

2000

|

3000

|

3000

|

2000

|

|

y

|

มม

|

1000

|

1500

|

1500

|

2000

|

6000

|

|

|

Z

|

มม

|

150-180

|

150-180

|

150-180

|

150-180

|

150-180

|

|

|

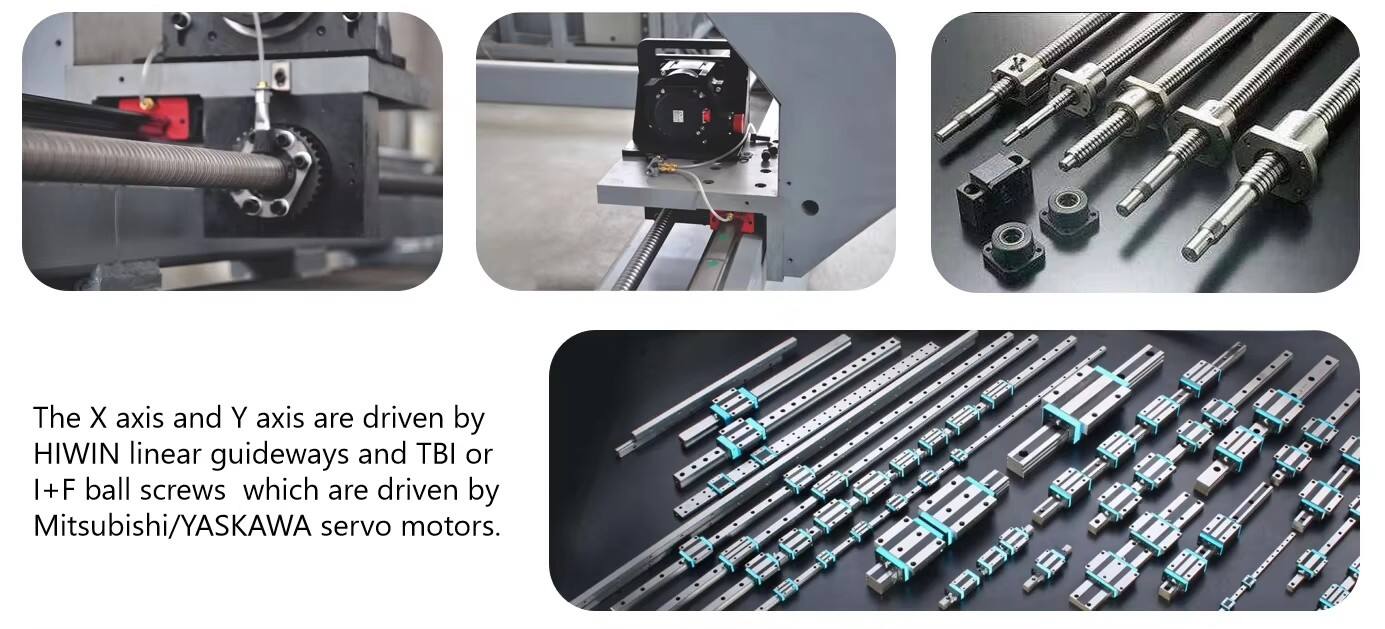

แกน X และแกน Y ใช้ HIWIN หรือ I + F ลูกสกรูและทางนํา;

มิตซูบิสิ หรือ ยาสกาว่า |

|||||||

|

ความแม่นยําในการตัด

|

มม

|

±0.1

|

|||||

|

ความแม่นยำในการ定位

|

มม

|

± 0.025

|

|||||

|

X,Y ความเร็วแบบแห้ง

|

ม./นาที

|

0-15 (หากต้องการความเร็ว 30m/min เราสามารถทําตามคําขอ)

|

|||||

|

ความเร็วในการตัด

|

ม./นาที

|

ในส่วนของวัสดุและความหนาของรายละเอียด

|

|||||

Q: ข้อดีของเครื่องตัดน้ําเจ็ตคืออะไร?

A: การแปรรูปแบบเย็น ไม่มีการปรับปรุงความร้อน ความสามารถในการตัดที่แข็งแรง สามารถตัดวัสดุได้เกือบทุกชนิด เครื่องเจ็ตน้ําบริสุทธิ์สามารถตัดวัสดุอ่อน เครื่องเจ็ตน้ําบดสามารถตัดวัสดุแข็ง แม้กระทั่งสามารถตัดวัตถุที่สามารถ วอเตอร์เจ็ทยังมีชื่อว่าเครื่องตัดทั่วไป

Q: วิธีเลือกโต๊ะตัดแบบมาตรฐาน

A: คุณจําเป็นต้องนําเสนอขนาดของวัสดุที่คุณต้องการในการประมวลผลหรือขนาดของโต๊ะตัด

Q: วิธีแก้ปัญหาขอบตัดเอียงโดยการตัดด้วยน้ำ 3 แกนคืออะไร?

A: การตัดด้วยน้ำเจ็ทไม่ได้เป็นการตัดตั้งฉาก เนื่องจากลักษณะทางกายภาพของน้ำเจ็ท หากต้องการการตัดมุมตั้งฉากที่แม่นยำ เราจะให้ระบบตัดแบบไดนามิก 5 แกนแก่คุณ ซึ่งสามารถทำชดเชยมุมเล็กในซอฟต์แวร์ได้

Q: อุปกรณ์ใช้ง่ายไหม?

A: ฐานบนโปรแกรมเจ็ทน้ําที่ดี ผู้ใช้สามารถเรียนรู้มันได้ง่าย และถ้าลูกค้าสั่งเครื่องใหม่ ช่างของเราจะให้การฝึกอบรมสําหรับเครื่อง