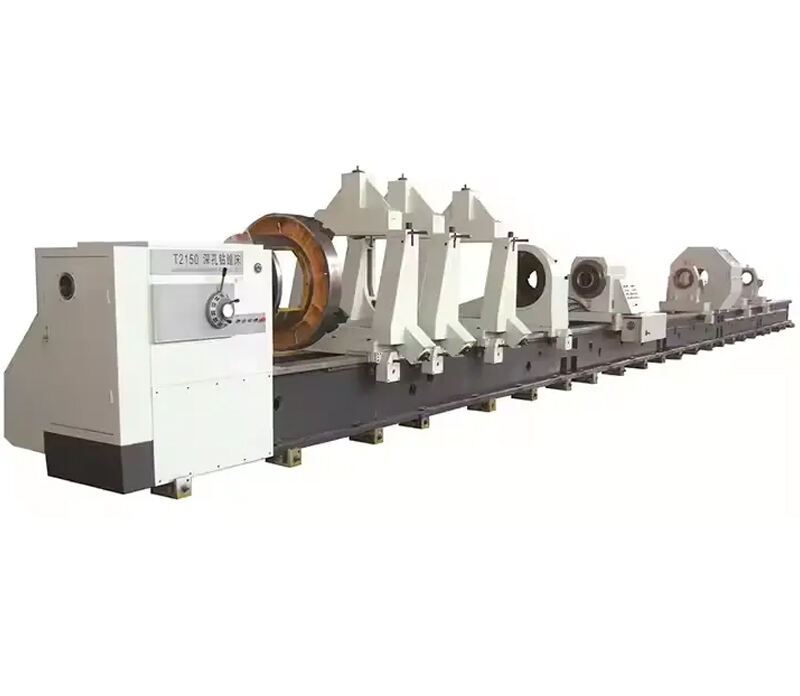

- Machine type: Spring Coiling Machine

- Weight (kg): 1950

- Warranty: 1 Year

- Place of origin: Jiangsu, China

- Brand name: ChuangYuan

- Video outgoing-inspection: Provided

- Machinery test report: Provided

- Core components: PLC, Engine, Motor

- Key selling points: Long Service Life

- Product Name: Cnc Spring Coiling Machine

- Color: Optional

- Size: 1900*2200*1400mm

- Max wire feed speed: 0-70m/min

- Cam instruction value: ±0.1°-±359.9°

- Cam rotation speed: 1-60rpm

Key attributes

Other attributes

| Machine type | Spring Coiling Machine |

| Weight (kg) | 1950 |

| Warranty | 1 Year |

| Place of origin | Jiangsu, China |

| Brand name | ChuangYuan |

| Video outgoing-inspection | Provided |

| Machinery test report | Provided |

| Core components | PLC, Engine, Motor |

| Key selling points | Long Service Life |

| Product Name | Cnc Spring Coiling Machine |

| Color | Optional |

| Size | 1900*2200*1400mm |

| Max wire feed speed | 0-70m/min |

| Cam instruction value | ±0.1°-±359.9° |

| Cam rotation speed | 1-60rpm |

| Wire feed servo power | 7.0kw |

| Cam servo motor | 7.0kw |

| Power supply | 380V±10%V50HZ |

| Weight | 1950kg |

Packaging and delivery

| Selling Units: | Single item |

| Single package size: | 200X230X150 cm |

| Single gross weight: | 1950.000 kg |

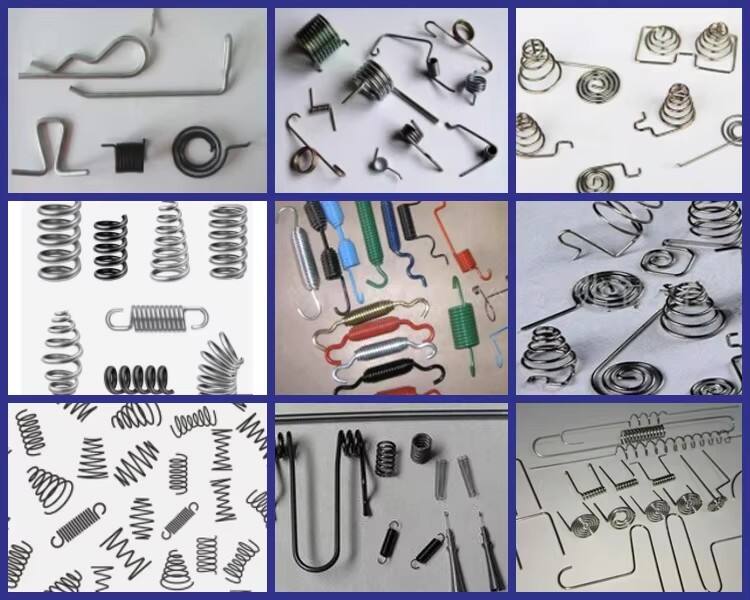

The HT series CNC spring machine computer has an English interface, which is easy to operate and accurate in positioning.The computer can control three to eight servo motors. All motors can operate synchronously or independently. It is equipped with precision detection and tracking equipment. If there are unqualified products, it can automatically stop. According to the working conditions on the evaluation screen, the external diameter angle of the products can be maintained at any time. The automatic mechanical parts are designed with automatic lubrication and oil supply to ensure the long-term operation of the equipment. The automatic stop design and automatic acceleration function of the wire rack make the production easier and more effective when wireless, broken or entangled. It is applicable to the production of double torsion springs, straight springs, pagoda springs, tension springs, rectangular springs, wire forming, steel sheet vortex springs, spring springs and various fancy springs, as well as miscellaneous and difficult special-shaped springs.

|

Spring Machine--Parameter

|

|||||||

|

Modle

|

HT-8208

|

HT-8212

|

HT-8320

|

HT-8322

|

HT-8335

|

HT-8345

|

HT-8350

|

|

Wire diameter of coiled material

|

ɸ0.15-ɸ0.8mm

|

ɸ0.2-ɸ1.2mm

|

ɸ0.4-ɸ2.0mm

|

ɸ0.2-ɸ2.5mm

|

ɸ0.5-ɸ3.5mm

|

ɸ1.0-ɸ4.5mm

|

ɸ1.0-ɸ5.0mm

|

|

Number of Axles

|

2 Axles

|

2 Axles

|

3 Axles

|

3 Axles

|

3 Axles

|

3 Axles

|

3 Axles

|

|

Wire feed instruction value

|

±0.01-±9999.99

|

±0.01-±9999.99

|

±0.01-±9999.99

|

±0.01-±9999.99

|

±0.01-±9999.99

|

±0.01-±9999.99

|

±0.01-±9999.99

|

|

Cam instruction value

|

±0.10°-±359.9°

|

±0.10°-±359.9°

|

±0.10°-±359.9°

|

±0.10°-±359.9°

|

±0.10°-±359.9°

|

±0.10°-±359.9°

|

±0.10°-±359.9°

|

|

Max outer diameter of coiled spring

|

Maxɸ20mm

|

Maxɸ20mm

|

Maxɸ60mm

|

Maxɸ60mm

|

Maxɸ80mm

|

Maxɸ80m

|

Maxɸ80m

|

|

Wire feed servo power

|

1.0KW

|

1.2KW

|

2.7KW

|

2.7KW

|

4.5KW

|

5.5KW

|

7.0KW

|

|

Cam servo motor

|

1.0KW

|

1.0KW

|

2.7KW

|

2.7KW

|

4.5KW

|

5.5KW

|

7.0KW

|

|

Power supply

|

380V± 10%V50HZ

|

380V± 10%V50HZ

|

380V± 10%V50HZ

|

380V± 10%V50HZ

|

380V± 10%V50HZ

|

380V± 10%V50HZ

|

380V± 10%V50HZ

|

|

Size

|

1000950 1600mm

|

10001000 1600mm

|

900900 1300mm

|

1500900 1900mm

|

17001300 2000mm

|

17001300 2000mm

|

17001300 2000mm

|

|

Weight

|

350kg

|

400kg

|

460kg

|

880kg

|

1500kg

|

1800kg

|

1950kg

|

Q:Are you manufacturer?

A: Yes, we are manufacturers of cut to length line,we have our own technical team, and about 80,000 sq.m workshop, welcome to visit us!

Q:What payment terms do you accept?

A: We are flexible on payment terms,we can also help you on financing,please contact us for details!

Q:What information will you need to make the proposal?

A: Coil weight,coil width,coil thickness,coil material, max. cutting length, cutting speed and your special requirements.

Q:What should I do to start a new business?

A: Please contact us immediately,we provide free pre-sales consultant service. Also we can help you to solve the worker training.

Q: Do you provide training and maintenance?

A: Yes. In order to your more efficiency for production, when the machine has arrived at the importer’ s port.

Our company will send engineers to installing the machine and responsible for training the worker of customer until they can operating the machine skillful.

During the warranty time, if the device can 't work normally, after receiving your notice, within 24 hours, we will send engineers to your factory for processing; If it is artificial damage,then need to charge a cost.

Each machine leaving the factory will be along with related English instructions including maintenance manual and operation manual.

Q:Why choose you?What is the difference between you and other Chinese supplier?

A: We have specialized in this area for over 20 years.Our cut to length line are exported to many countries in the world. You can get higher quality product & better professional service from Hitech with same price.

Steel Coil Cut to Length Line for Steel Coil Straightening and Cutting

Factory Wholesale DS703A CNC EDM Small Hole Drilling Machine edm Super Drill machine

High-accuracy Hole Boring Machine Horizontal Deep Hole Drilling and Boring Machine TK2120

Machining Center 5 Axis Moving Column Gantry Machining Milling Center Automatic Tool