EDM Processing

Machine main parts features

Castings

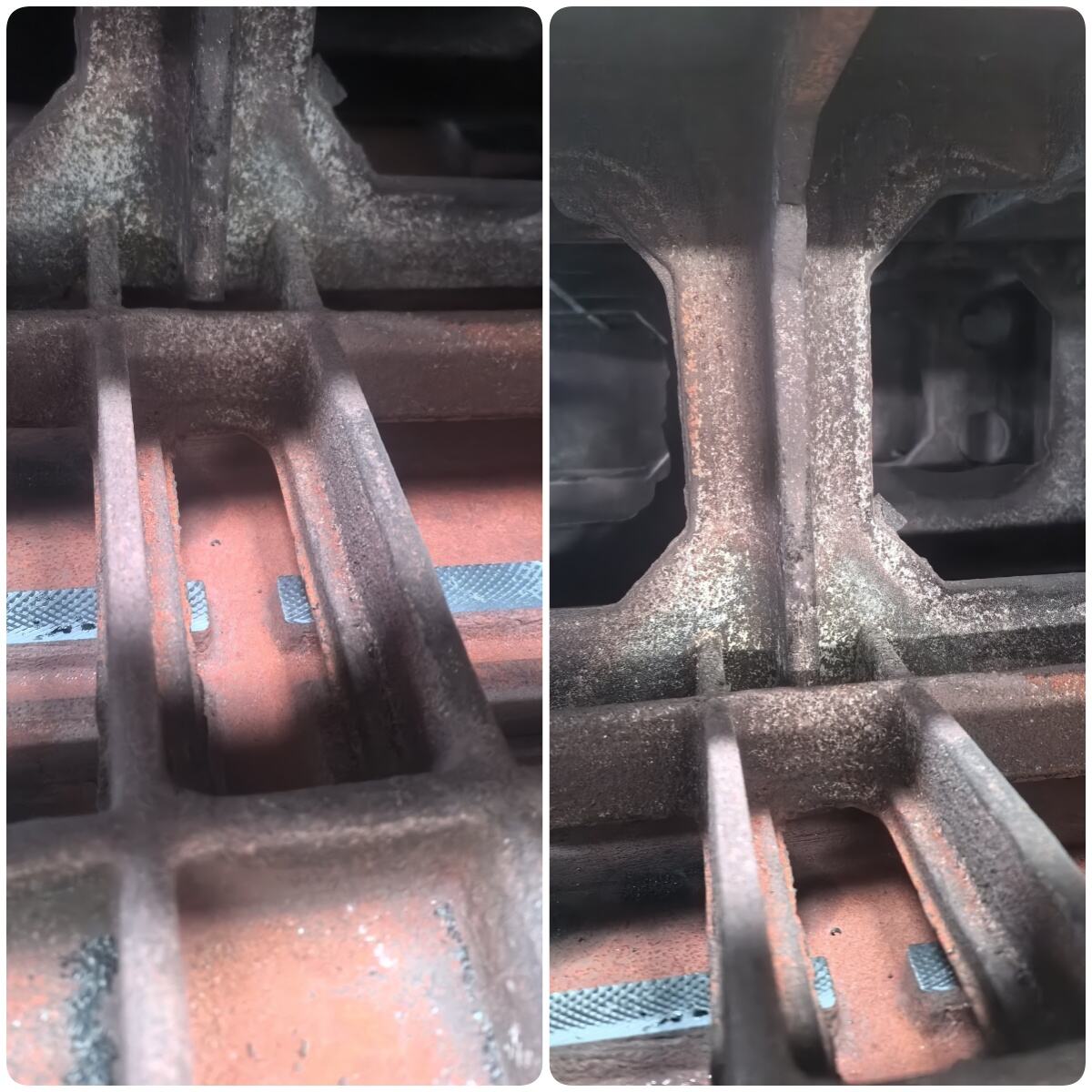

All castings are tempered through 600°C in the tempering furnace, to remove internal stress and enhance their rigidity and stability.

We added enlarged and thickened reinforcement ribs in upper, lower and middle of the machine beds. Enhanced its stability and will not deform even after prolonged use. Can increase service life at the same time.

Three layers of thickened reinforcement ribs are designed in the middle of the column. it not only separates the wires from the lead screw, but also enhances the stability of the column, making it less prone to deformation. Ensure the machining accuracy.

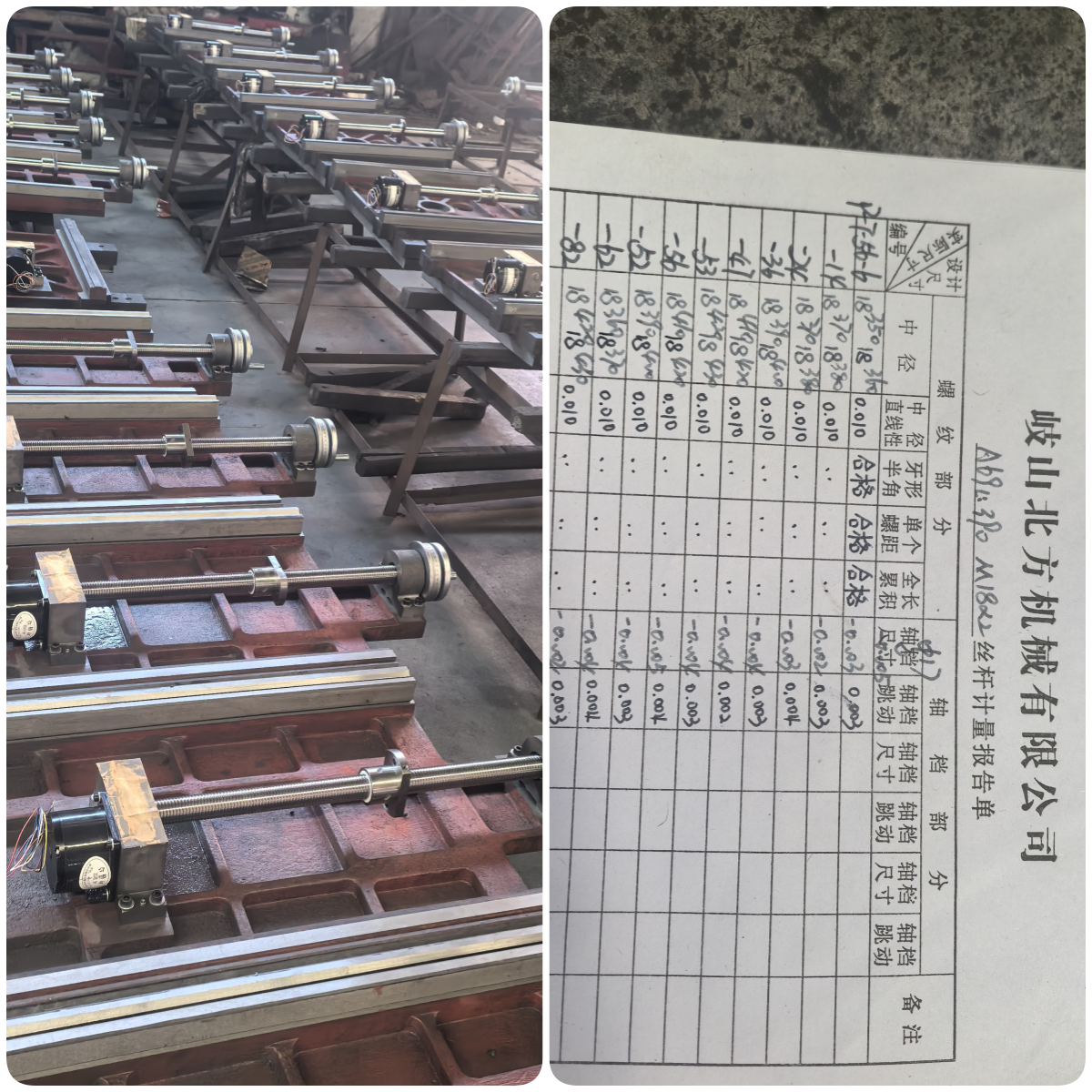

All lead screw use famous and legitimate NMC brand. Through strict accuracy detection.

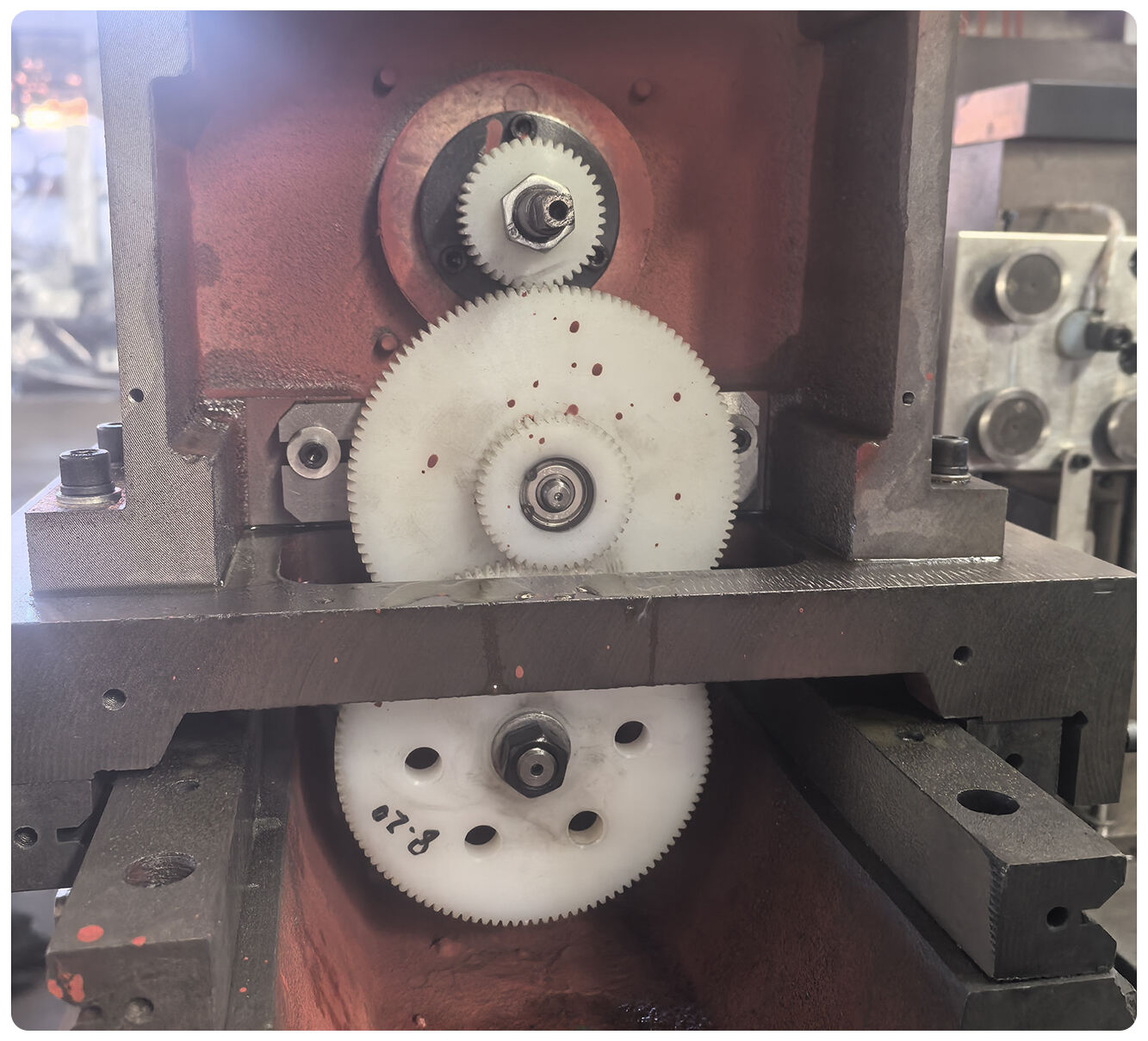

The wire drum transmission adopts gear transmission, with longer serve life. instead of synchronous belt. Because synchronous belts are prone to aging, becoming loose, and even breaking.

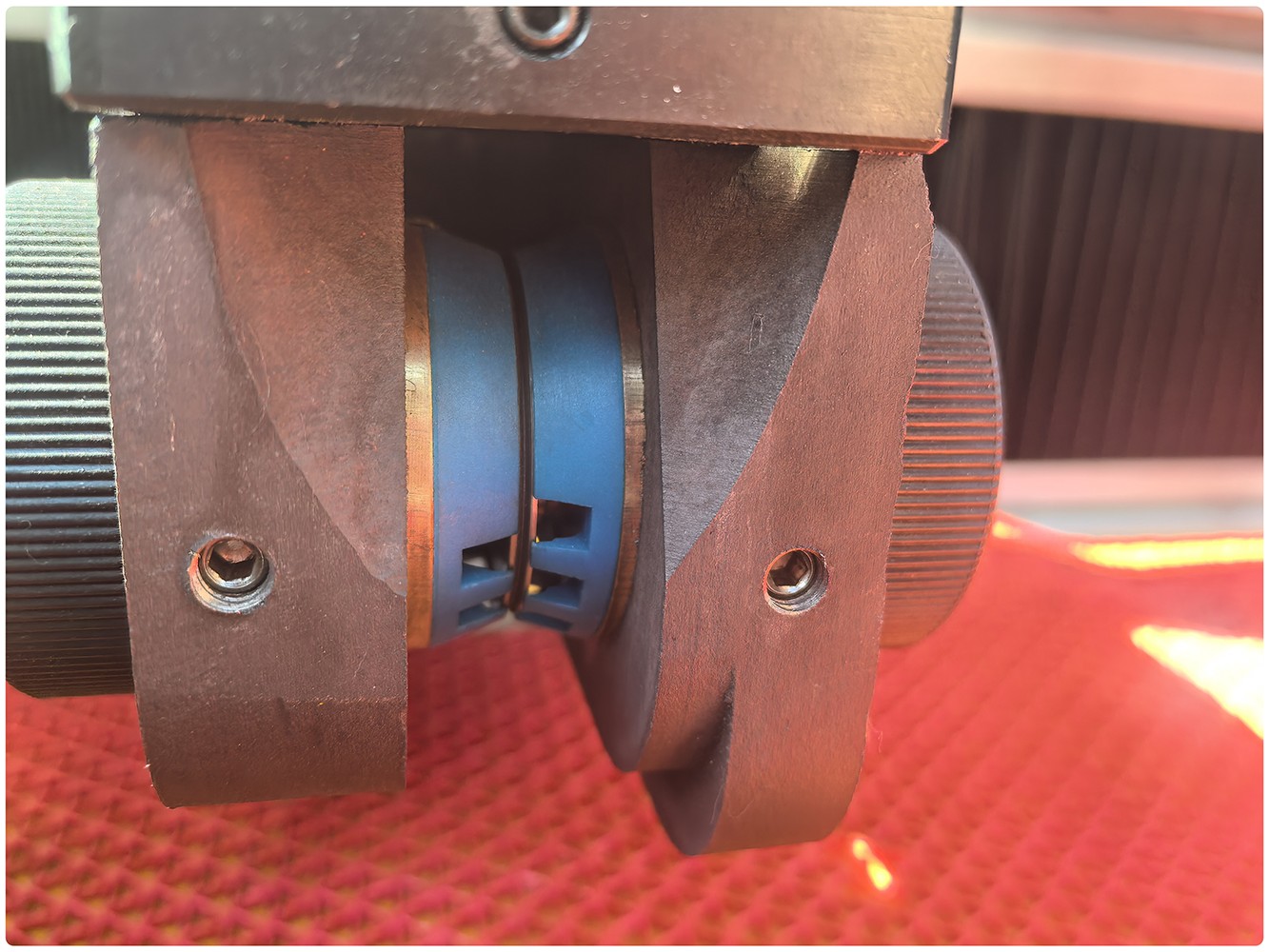

All machines use special easy to thread guide wheels, which are more convenient for threading than common guidewheel.

We use Renishaw laser interferometers to measure the positioning accuracy of each device. Each machine can accurately pass the machining positioning test of the jumping die.